That’s a good question, and the anwser is yes – if you use a quality carpet bar. A walk down a flooring aisle at any home improvement store will expose the utter lack of a quality carpet bar in the retail Home Improvement world. A carpet bar certainly isn’t the first thing one thinks about when replacing or repairing flooring. It’s like twelfth on the list after the first eight items. It’s often an afterthought. Why is that?

I think one needs to ask, exactly what is a ‘carpet bar’? It’s name is a bit misleading in a way. It sounds like a bar made of carpet, right? Yeah, no. A carpet bar is a flat or slightly raised aluminum or wood product that is used to cover a seam in a floor, whether it is carpet, VCT, or linoleum. Most of what you can find at a home improvement or hardware store is designed to be a transition from type of flooring to another, i.e., linoleum to carpet. More specifically, it is used to transition when one level of flooring is slightly higher than the next level it abutts to. Most often, these are used to transition from carpet to another type of flooring such as carpet to linoleum as mentioned previously. However, that is not always the case. They can also be used when transitioning from one style or color of carpet to another, or one type / color of hardwood to another. The basic premise is to smooth the transition as much as possible, both asthetically and practically. These are generally inexpensive product that are used to keep costs down. Transitioning from one floor to another without a transition / carpet bar is expensive, however, it is also much more asthetically pleasing and is a great value add for the structure.

In

The carpet bar we use is one that serves a slightly different purpose. Like the carpet bars / transition bars found at retail outlets, it is designed to save time and money when costs are at the forefront of the project. Where the carpet bar we use differs the most is that it is tying two floors at the same level together in a way that eliminates the additional cost of closing up a VCT floor or carpet floor.

When we close up a building there is always that line where the floors meet called the marriage line. Depending on how the VCT, carpet tile, or roll carpet was installed, there may or may not be a seam in the flooring or carpet directly over the marriage line. That in itself will often times decide how much work will be required to close the floor up. In almost every tear down, there will almost always be a need to cut through the fixall at the very minimum, allowing the building to be split. When a full piece of VCT, carpet tile or roll carpet bisects the marriage line, it is a definite requirement that they be cut. Carpet tile and roll carpet can be cut with a utility knife and peeled back, then the fixall can be cut with a skill saw or sawzall. The only time this isn’t the case is if the building was brand new and new subflooring that bisects the marriage line was installed during its initial set. Regardless, the floor will need to be cut.

In a previously used building, the flooring has almost always been cut when the unit was dismantled the last time. That cut has to be repaired in some fashion to make the building fully usable; there is a lot of labor intensive prep work that goes into that, especially for an older VCT floor. The photos below are a good example of an older VCT floor that needs to be repaired To repair that VCT floor at the marriage line, the old flooring needs to be removed or peeled back, the subfloor prepped, and new flooring installed. If the VCT was properly installed, it should be very well secured to the floor, which will require the tile to be heated with a torch to soften the adhesive the adhesive, which will allow the release of the tile when scraped up. Often times, though, the VCT is old and cracking, and the adhesive no longer adhering the tile to the floor properly. Once the tile is removed, the old adhesive and plaster of Paris / Fixall needs to be removed. Once that is done, the floor is sanded down to the subfloor. Upon completion of that task, new plaster of Paris / Fixall is spread to fill the gab between the two floors and allowed to dry. Once dried, that needs to be sanded smooth and new adhesive applied and allowed to sit overnight to cure. The next day, the new VCT can be installed and weighted (rolled with a heavy roller to ensure full contact between the tile and the adhesive). That is providing everything goes according to plan, the ambient temperature is high enough to allow the adhesive to cure, and no other issues arise. This process is usually a two day process with all of the prep work taking place on the first day, and the installation of the tile on the second day.

The older the building, the more likely it is for some fairly indepth flooring repair is going to be needed. Depending on how the VCT, carpet tile or roll carpet is installed, there may or may not be a seam directly over the top of the marriage line. Sometimes we are fortunate and the flooring has been repaired on a recent previous set. When this is the case, and extensive floor repairs aren’t required, we still need to provide some sort of closure to the floor, something to clean up the look of the marriage line. No matter how straight the flooring is cut, it is never really completely straight. It needs to be protected so the edges of the cut flooring doesn’t chip or crack, or carpet doesn’t get hooked and run, and as mentioned before, it just needs to look clean. This is where a quality carpet bar comes into play.

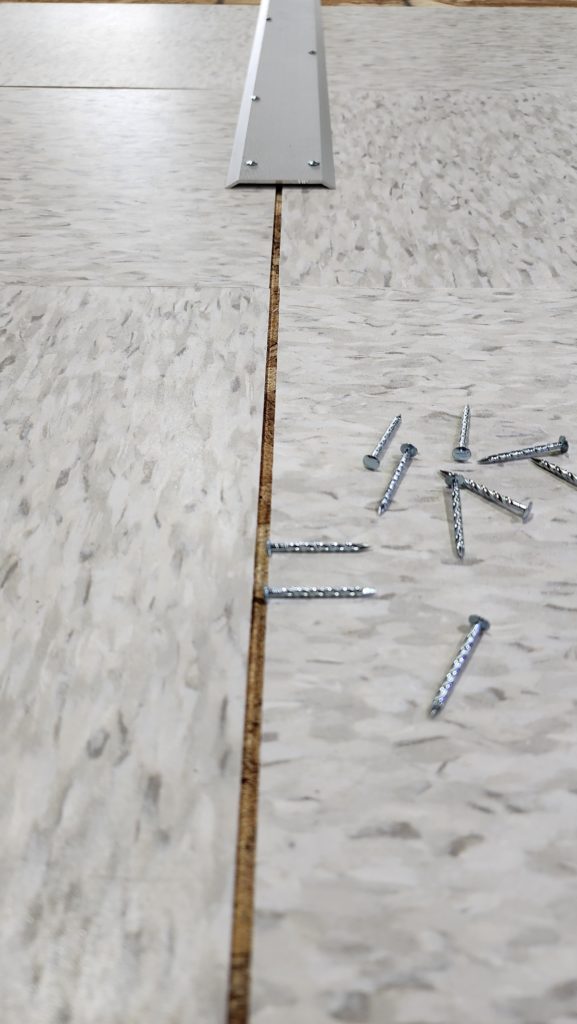

EZ Systems worked with an aluminum extruder to develop our own carpet bar. The carpet bar we ultimately agreed upon is 2.5″ wide with an alternating nail hole pattern with the holes lined up near the edge of the carpet bar to provide the best anchorage for the nails or screws to hold the bar in place. The bar is 5/32″ thick with a double bevel design that raises the bar to a heigh of 5/16″ above finished floor. The top of the carpet bar is grooved for traction and asthetics. The carpet bar can be nailed down or screwed down. Standard carpet nails work well with the carpet bar. One of the challenges with previous carpet bar we used was that the nail holes ran right down the center of the carpet bar, which usually put them right in the middle of the gap between the two floors. With our product, the nail holes are spread out across the width of the bar, allowing the nails or screws ample bite into the subfloor. Care does need to be taken to not get overly eager when setting the nails or screws as the carpet bar can be divoted if care isn’t taken during installation.

Our carpet bar comes in twelve foot sticks and are usually shipped in circular shipping tubes, five or six to a tube depending on the size of unit they’re going in. We can ship to anywhere in the US. As of this writing, we currently have over 300 sticks in inventory, ready to ship. Feel free to reach out to us if you have any questions our would like a sample shipped to you!